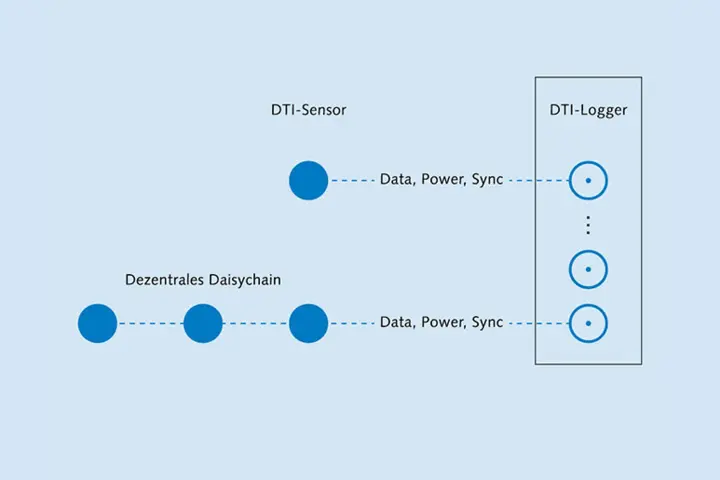

Through the bus topology to the data recorder, many different sensors can be used on a vehicle with little effort, for example, wheel force transducers, accelerometers, force sensors, etc. The setup of complex test setups is thereby greatly simplified, both in the areas of vehicle dynamics, durability and crash testing.

What advantages does DTI offer?

- Fast, easy and straightforward wiring

- Automatic sensor detection thanks to TEDS (Transducer Electronic Data Sheet)

- Easy access to the installation position, calibration values and physical variables

- Step-by-step configuration using the KiCenter PC software

- Interference-free, synchronized data transmission via DTI logger

Where is DTI used?

DTI is used in automotive engineering. Within the scope of comprehensive vehicle dynamics, durability and tire tests, a host of physical variables such as acceleration, brake pressure, expansion, steering forces and torques, side-slip angle, temperature and others are recorded. With the help of this data, vehicle engineering is optimized.

![[object Object] [object Object]](https://kistler.cdn.celum.cloud/SAPCommerce_CMSTeaser_560x375/934-667_web.webp)