Protecting the energy and infrastructure sector is crucial for a safe and sustainable future: various internal and external factors may cause wear or malfunction. Permanent availability, durability, and efficiency of (renewable) energy sources, power grids, and civil structures require measurement technology that enables Structural Health Monitoring through precise data.

Kistler is your competent partner and supports you with a broad portfolio of measurement technology and specific know-how for different applications. Our solutions play their part in environmental simulations in the laboratory as well as for continuous monitoring of plants and structures. For example, Structural Health Monitoring (SHM) includes detecting microcracks or leaks, the continuous monitoring of historic buildings, or analyzing the structural behavior of turbine blades.

Tailor-made condition monitoring solutions for the global energy and infrastructure sector

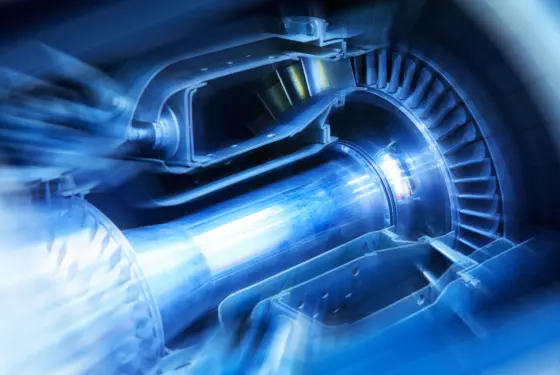

In the hydroelectric power sector, Kistler supplies sensors to detect cavitation and for pressure pulsation and water hammer monitoring. Ceramic shear sensors from Kistler are used for modal analysis of wind turbine blades; the oil and gas industry opts for Kistler sensors to detect leaks on pipes and valves, and for flow testing and monitoring. For nuclear power plants, Kistler can offer sensors to measure and analyze flow-induced vibrations in the air, and in static as well as pressurized water. Operators of gas turbines depend on high-temperature technology from Kistler to test and monitor the combustion process. In the Civil Engineering sector, our systems are employed to determine the structural health of bridges and historic buildings, for example in earthquake regions.

State-of-the-art solution for Structural Health Monitoring (SHM) and condition monitoring in the energy and infrastructure sector from Kistler – find more information in the application sections below or make direct contact with a local sales expert.